Structure of Potato Layers as a Hive-like Arrangement

In an exciting development, researchers have discovered a novel way to create insulating plates using potato starch. Known as potato plates, these innovative creations are not only effective at insulating hot food and liquids, but they also feel cool to the touch, making them a safe and practical solution for everyday use.

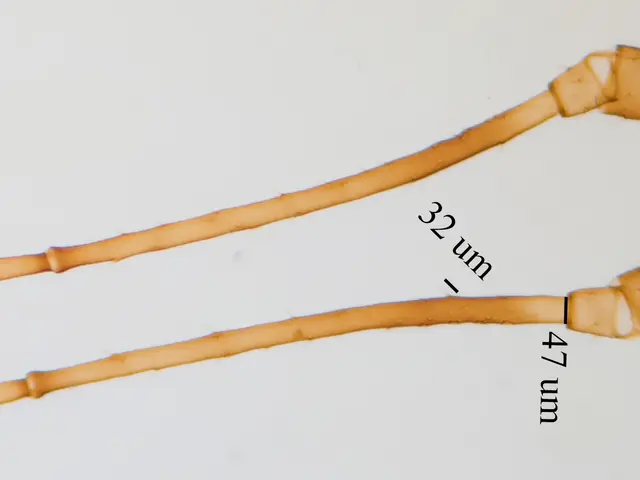

The secret to potato plates' insulating abilities lies in their unique honeycomb structure. Similar to polystyrene, this structure allows potato plates to provide excellent insulation, trapping heat and preventing it from being transferred. This is achieved through the compression moulding process, where potato starch is heated, gelatinized, and then consolidated under pressure. The starch molecules rearrange and form a matrix with voids or cell-like cavities, which organize into a honeycomb-like pattern.

One molecule of potato starch can expand up to 400 times during this process, creating a lightweight, cellular microstructure. This results in a material with lower density and improved mechanical characteristics, making it an ideal choice for insulation. The formation of air voids mimics natural cellular structures, a principle often used in producing biomaterials with low thermal conductivity and lightweight properties.

The creation of potato plates involves two hot surfaces, one on the bottom and one on the top. In the initial 2 seconds, the mix forms a skin that becomes impermeable. The water in the mix escapes through the centre and out through vents during the potato plate creation process.

Potato plates are not only effective at insulating heat, but they are also suitable for holding hot food and liquids without transferring the heat. This is due to their honeycomb structure, which allows them to provide an effective barrier against heat transfer.

Cereal starch, when used, results in a denser and heavier product compared to potato starch. However, the insulation properties of potato plates remain unchanged, making them a versatile choice for various applications.

In conclusion, the compression moulding of potato starch creates a honeycomb structure by gelatinizing starch under heat and pressure, then solidifying in a way that traps air voids or forms pores, resulting in a lightweight, cellular microstructure that resembles a honeycomb. This process hinges on the physical and thermal properties of starch and the specific moulding conditions used. The insulating properties of potato plates make them a promising alternative to traditional insulation materials, offering a sustainable and eco-friendly solution for heat insulation needs.

- The innovative honeycomb structure of potato plates, similar to that of polystyrene, makes them ideal for health-and-wellness applications, such as insulating hot food and drinks without feeling hot to the touch.

- In environmental-science and space-and-astronomy, the lightweight and cellular microstructure of potato plates, created through compression moulding, could potentially contribute to reducing the weight of spaceships or other equipment, thus promoting a more sustainable climate-change solution in space travel.

- To further explore the potential of potato plates, researchers could conduct additional studies on their nutritional properties, focusing on the degradation of starch under various conditions and its impacts on human consumption, broadening their applications to fitness-and-exercise and overall health-and-wellness.